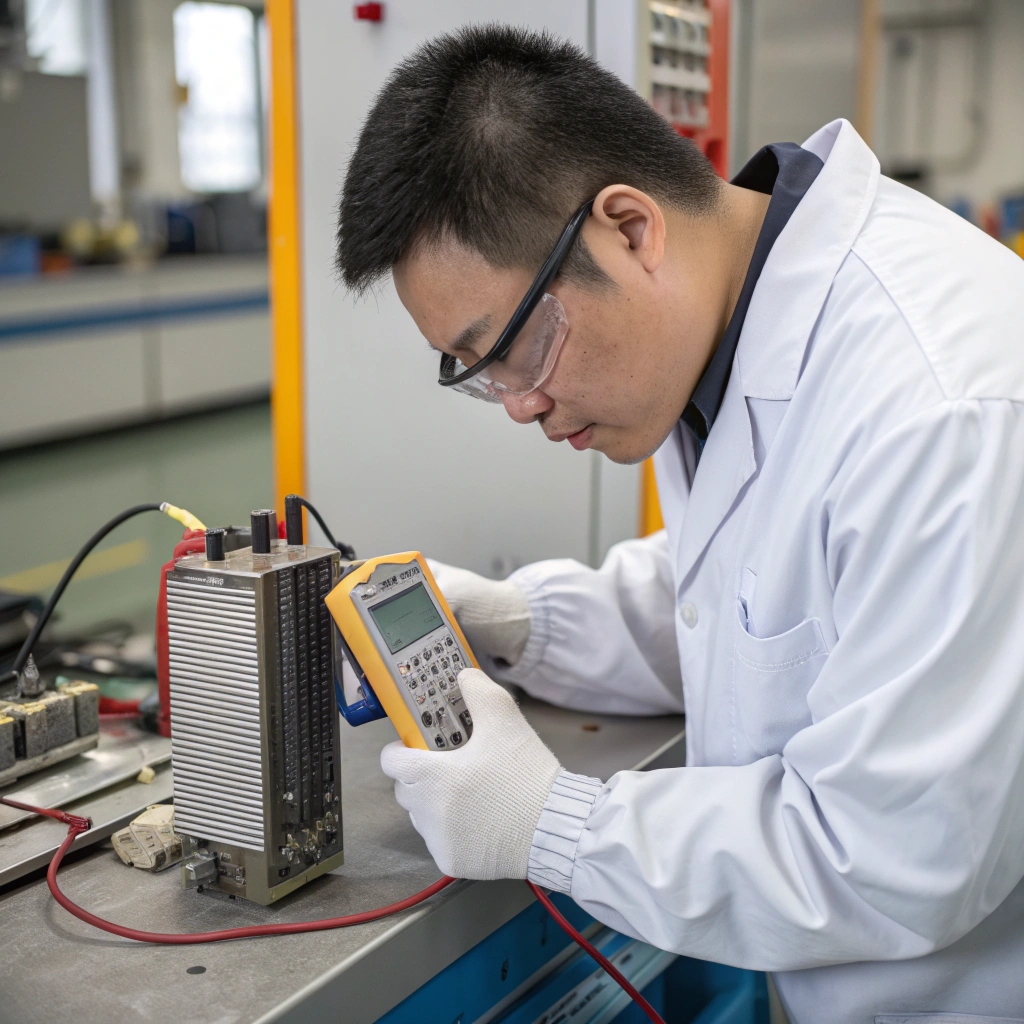

Struggling with equipment failures from the wrong PTC heater? This leads to poor performance and constant headaches. You can double your device's reliability by simply mastering four key parameters.

Choosing the right PTC heating element is crucial for performance and safety 1. You must focus on four key parameters: Curie temperature, rated current, resistance jump magnitude, and environmental suitability. Getting these right ensures your device operates reliably without frequent failures or safety risks.

I've seen countless projects suffer because of a poorly chosen PTC. A simple component, yet it can be the single point of failure that brings down an entire system. The good news is that avoiding these pitfalls is straightforward once you know what to look for. In my years of experience, I've boiled it down to these four critical checks. Let's walk through each one so you can select your next PTC with total confidence and ensure your product is built to last.

How do you pick the right Curie Temperature?

Picking the wrong Curie temperature 2 can cause your device to either overheat or never get warm enough. This can damage your product or create a serious safety hazard.

The ideal Curie temperature for a PTC heater should be 10°C to 20°C higher than your device's normal operating temperature. This provides a safe buffer, preventing false triggers during normal use while ensuring swift protection when overheating occurs.

The Curie temperature is the PTC's built-in "brake." It's the specific temperature where the material's electrical resistance suddenly shoots up, drastically reducing the current flow. This self-regulating feature is what makes PTCs so brilliant. Think of it as a smart thermostat that doesn't need any extra circuits. The key is setting that trigger point correctly. If it's too close to the operating temperature, the heater will constantly throttle itself, never reaching full performance. If it's too high, it won't kick in to protect your device until it's already too late. I always use a simple table to guide my clients.

| Application | Normal Operating Temp. | Recommended Curie Temp. | Reason |

|---|---|---|---|

| Lithium Battery Heating | 40°C - 60°C | 60°C - 80°C | Protects battery cells from damage. |

| Electric Iron | 140°C - 160°C | 160°C - 180°C | Maintains stable heat without overheating. |

| Incubator | 37.5°C | 50°C - 60°C | Provides gentle, safe heating for sensitive use. |

This 10-20°C buffer zone is the sweet spot for reliability and safety.

What about the rated current 3?

Does your PTC heater trip unexpectedly, especially when you first turn the device on? This makes your equipment seem faulty and is incredibly frustrating for the end-user.

Your PTC's rated current must be 20% to 30% larger than the device's normal working current. This is essential to handle the initial inrush current 4 from components like motors, preventing the PTC from mistakenly triggering its protection mode during startup.

I remember working with a client whose new product kept failing during quality control. The issue was that the PTC would trip every time they powered on the device. The problem wasn't a fault; it was inrush current. Many devices, especially those with motors or large capacitors, draw a huge spike of current for a split second upon startup. This spike can be several times the normal operating current. If your PTC's rated current is too low, it sees this spike as a dangerous overload and shuts the system down. That's why building in a 20-30% buffer is not just a recommendation, it's a necessity for reliability. It gives the system enough room to handle these normal startup surges without causing false alarms.

| Component Type | Normal Current | Inrush Current Spike | Required PTC Rated Current |

|---|---|---|---|

| Simple Resistor | 2A | ~2A | > 2.4A |

| Small Motor | 2A | ~8A (for milliseconds) | > 2.4A |

| LED Array | 2A | ~4A (for milliseconds) | > 2.4A |

This simple margin makes the difference between a product that works every time and one that's a constant source of support tickets.

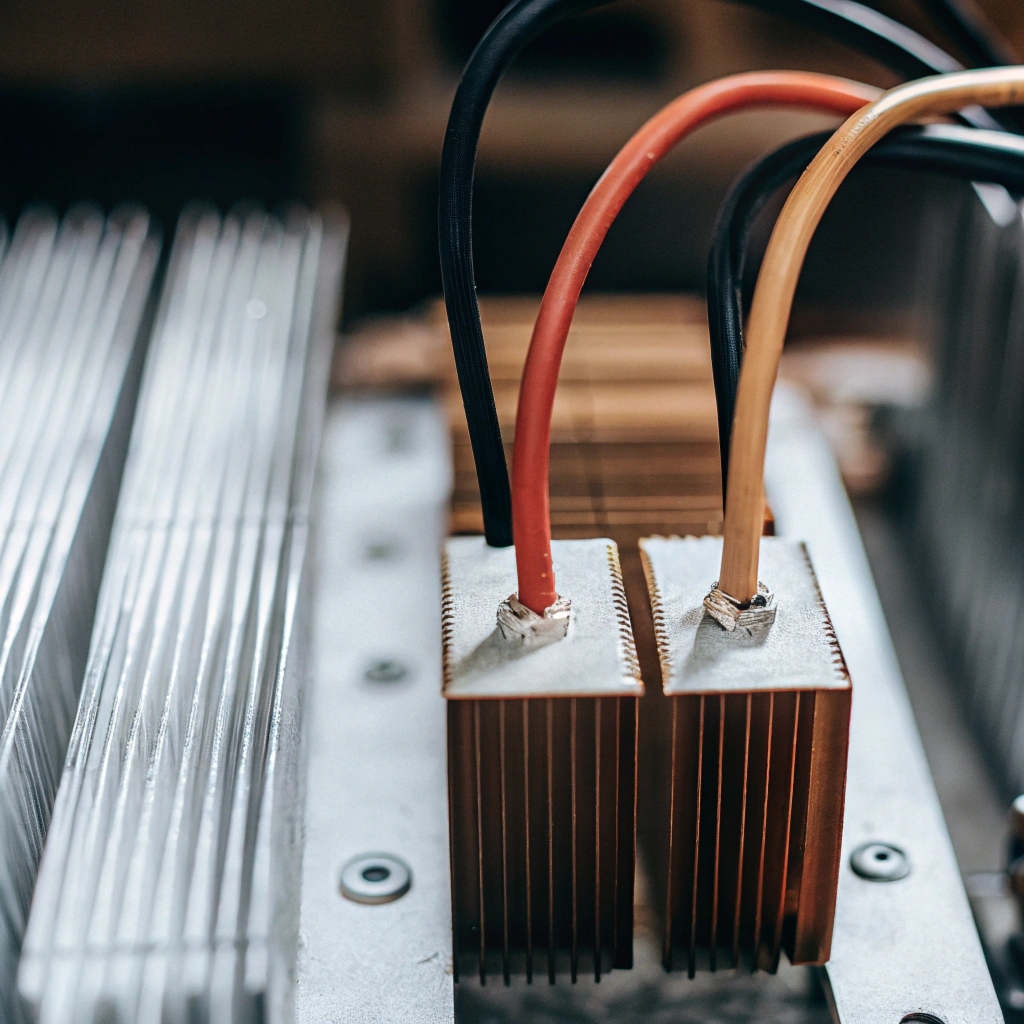

Does the resistance jump really matter?

Your PTC is either too slow to prevent damage or so sensitive it creates unnecessary alerts. One extreme leads to catastrophic failure, the other to a "boy who cried wolf" situation.

Yes, the resistance jump magnitude is critical. For fast-acting overcurrent protection, choose a PTC with a jump of over 100,000 times. For gentle temperature stabilization or pre-warning systems, a lower jump of around 1,000 times is more suitable.

Think of the resistance jump as the PTC's reaction intensity. It's how hard it hits the brakes when it reaches the Curie temperature. Not all applications need the same response. A project I worked on required an immediate shutdown if a short circuit occurred. We needed to protect sensitive downstream electronics. For that, we chose a PTC with a massive resistance jump. The moment it sensed an overcurrent, it effectively became an open circuit, instantly cutting power. In contrast, another client needed a heater for a wax warmer. They didn't want the power to cut off completely, they just wanted it to ease off as it reached the target temperature. For this, a PTC with a much smaller resistance jump was perfect. It provided a soft, regulating effect rather than a hard stop.

| Application Goal | Required Reaction | Recommended Resistance Jump | Example Use Case |

|---|---|---|---|

| Safety Cut-Off | Instantaneous, aggressive | > 100,000x | Short-circuit protection |

| Pre-Warning Alert | Noticeable, but not halting | ~10,000x | High-temperature alarm |

| Temp. Stabilization | Gentle, gradual | ~1,000x | Small appliance heating |

Matching the jump to the job ensures your PTC is not just a component, but an intelligent part of your design.

How does the environment affect your PTC choice?

You used a standard PTC in an outdoor device, and it failed within months. This leads to expensive field repairs, product recalls, and damage to your brand's reputation for quality.

The operating environment dictates the grade of PTC you need. For harsh outdoor or high-temperature industrial settings, use a robust industrial-grade PTC 5 rated for over 150°C. For stable indoor applications like home appliances, a standard consumer-grade PTC is sufficient and more cost-effective.

You wouldn't wear summer clothes in a snowstorm, so don't use a consumer-grade PTC 6 in an industrial setting. The materials and construction are completely different. Industrial-grade PTCs are built to withstand moisture, vibration, and extreme temperature fluctuations. I once consulted for a company making heating systems for transport vehicles. They had tried to save money by using consumer-grade PTCs, which were failing constantly due to the combination of engine heat and outdoor cold. We switched them to a sealed, industrial-grade PTC. The failures stopped immediately. On the other hand, for a simple coffee mug warmer used in an office, an industrial PTC would be expensive overkill. A standard consumer-grade component is perfectly reliable in that stable environment.

| Environment | Key Challenges | Recommended PTC Grade | Cost Implication |

|---|---|---|---|

| Indoor / Consumer | Cost sensitivity, stable temps | Consumer Grade | Lower |

| Outdoor / Automotive | Moisture, vibration, temp swings | Industrial Grade (Sealed) | Higher |

| Industrial / Factory | High ambient heat, chemicals | Industrial Grade (>150°C) | Higher |

Choosing the right grade isn't about over-engineering. It's about matching the component's durability to the reality of its working life, saving you money and headaches in the long run.

Conclusion

Selecting the perfect PTC is easy. Just focus on the Curie temperature, rated current, resistance jump, and the operating environment. Get these four things right for a superior, reliable product.

Exploring how PTC heaters balance performance and safety can improve your device's reliability. ↩

Understanding the right Curie temperature is essential for ensuring safety and performance in PTC heaters. ↩

Knowing how to calculate the rated current helps prevent equipment failures and ensures reliable operation. ↩

Understanding inrush current is vital for selecting the right PTC to avoid false tripping. ↩

Industrial-grade PTCs are built for durability, making them ideal for harsh environments. ↩

Knowing when to use consumer-grade PTCs can save costs while ensuring reliability in stable environments. ↩